Some people also use induction motors to generate electricity with. They need a modification on their capacitors in order for them to self start. They must be turned fast. Gearing is needed. Some people even rewind these motors to get the RPM at which they must be turned down.

Some more things used for wind generators: 1)Treadmill motors.

2)Car windscreen wiper motors. I came across one wind turbine design using a windscreen wiper motor, but it was in Japanese and I could not view it on the internet, you have to order a hard-copy. These motors are geared down so they turn at about 60RPM. The inside motor turn at about 2500RPM. The wiper motor I checked could not be turned from the outside, only the motor can turn it from the inside because of the gear configuration.

Blade Design

PVC blades made of PVC pipe is most popular since it is very easy to make and the cost is very low. Some people don’t even pay for the pipe at all, they get offcuts at construction sites. If you use the black sewer pipe PVC, keep in mind that it gets brittle in the sun after some time. The blades need to get painted with a UV resistant paint if you want them to last. White or blue gutter type of PVC downpipes do not need painting. Designs turning an Ametek DC motor or Alternator will have blades sized about 48 inches ( 1.21 meters ) in length using a pipe with a diameter of 8 ( 20cm) – 12 ( 30cm ) inches.

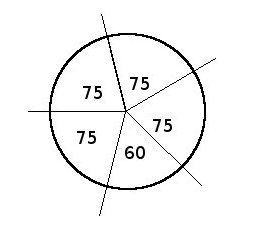

The pipe is cut into 5 sections, 4 sections of 75 Degrees of the pipe, and one remaining section will be 60 Degrees:

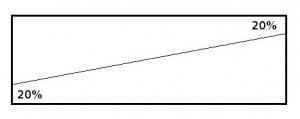

Then take each of the 75 Degree peaces and cut them across diagonally so that each small tip is about 20% of the full width:

Here is a photo of PVC Blades on a DIY Stepper motor turbine:

You will end up with 8 blades + 1 if you use the 60 Degree piece also. Thats 3 sets of blades. So you can make 3 turbines with one pipe or you have 2 spare sets.

Wooden blades can be made to cut through the wind better than PVC blades, but it takes a lot of effort to make such blades and can take a lot of time. The wooden blades do not work that much better. PVC blades are easy to replace so it is no problem if a storm broke them. They are also slightly elastic which makes them tolerant to jerky winds. The ease and low cost with which PVC blades can be made, causes it to be the more popular choice.

Aluminium is also an option, and a good option if you need durable blades which catches the wind very well. These blades are expensive and are not usually made by DIY people. They can be found on ebay.